A factory opens its doors

“Open Factory” means “open production”: once a week, Mountech Co. Ltd., Tatonka’s production facilities in Vietnam, opens its doors. Anyone who is interested – consumers, retailers, journalists, industry specialists, NGO representatives – is welcome to visit the facility while it is in production.

This project, which is unique in the outdoor industry, was initiated in 2011 and very quickly established. It was made possible because the Bavarian family company Tatonka is the sole owner of Mountech Co. Ltd.

Social responsibility – transparency creates trust

For many people, it is becoming increasingly important to purchase products under socially responsible, fair conditions. Companies that use contract manufacturing can prove that their production is fair with seals and certificates. Tatonka is going its own unique way with “Open Factory”, and opening up its facilities to anyone who is interested – not least because seals and certificates can also be questioned by critics.

The Open Factory project demonstrates how principles and convictions can actually be lived and experienced. Anyone is welcome to see Tatonka’s sustainable social commitment for themselves.

Something very special: its own production facilities

Ever since the Tatonka brand was first founded, its products have all been made at the company’s own facility, Mountech Co. Ltd. This was set up at the end of the 1980s under the company’s own management, and is still run that way today. Managing director Andreas Schechinger, son of the company founder, is responsible for all decisions, and travels to Vietnam several times a year, each time for several weeks.

From the beginning, the aim has been to establish the production to European standards in order to manufacture high-quality outdoor equipment. Naturally, this means training staff appropriately on site, and creating the framework conditions for a close co-operation – because the development department, administration and delivery warehouse are all in Dasing in Bavaria/Germany.

Social responsibility towards staff – in Germany and Vietnam – is a lived part of Tatonka’s corporate philosophy.

Statistics

Our aims

When we first started Open Factory in 2011, it was important to us to provide anyone who was personally interested in our facilities with access to them, as well as having a production facility that was certified to the internationally recognised social standard SA8000. Some people are interested in our social standards, others simply in how a backpack is made. At the end of their tours, lots of visitors say, “We had no idea that making a backpack is so complicated.” They then had a different appreciation of our products, and for the social and quality standards under which we operate in Vietnam. That is why our Open Factory project is also in tremendous demand with groups of students and government delegations from other Asian countries. They find out more about our social project, and then pass this information on in their respective countries.

I first saw MOUNTECH in 1993, and much water has flowed down the Saigon. Over the years, many retailers, suppliers and customers have visited us and found out more about our production facilities. It’s actually embarrassing to have to talk about self-image, but on the other hand, I think it’s good if the individual TATONKA user can also experience and appreciate our corporate philosophy. The Open Factory offer has also been accepted by lots of NGO’s, universities and so on in Asia. But why not pop in and have a look – we’ve nothing to hide!

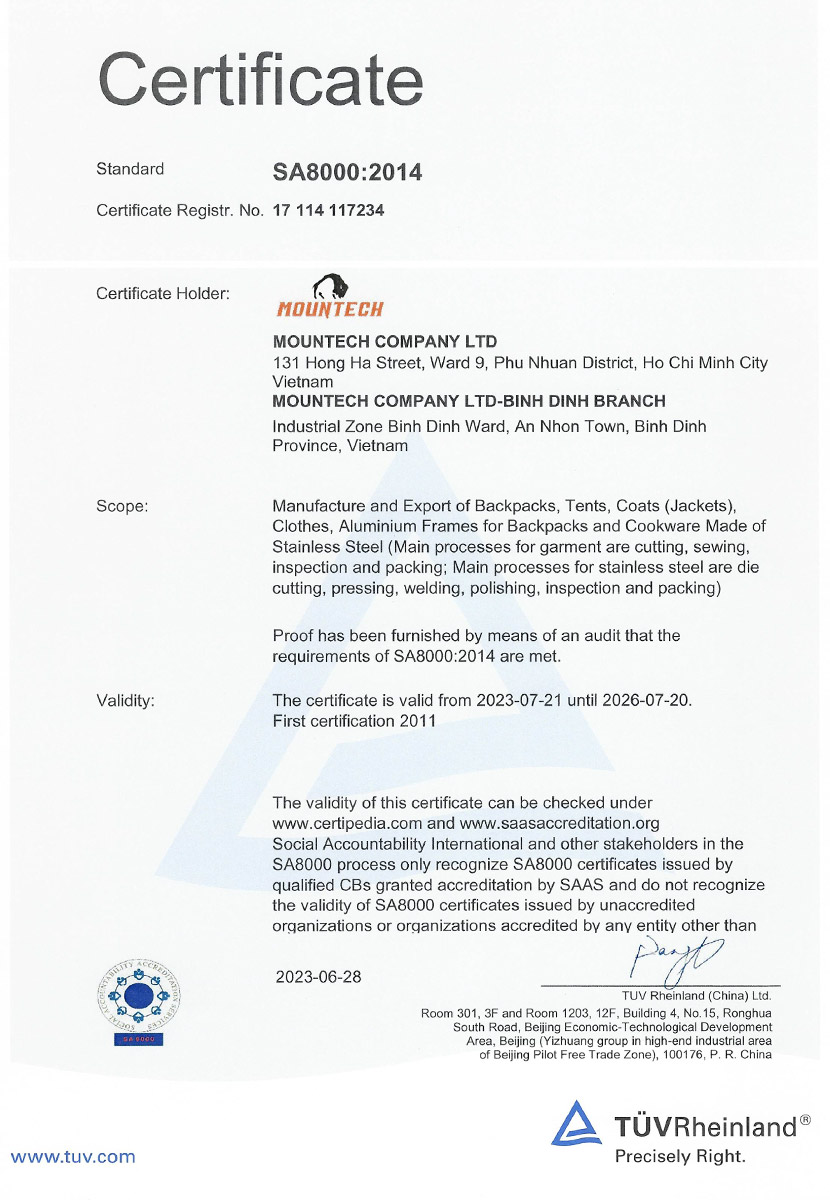

SA 8000:2014 – Certification or company responsibility

The social standard was called into being in 1987 by the non-profit-making organization SAI (Social Accountability International, registered office in New York). It enables companies with own production to prove social responsibility and demands the most comprehensive and most far-reaching standards. These are based on national laws, on the human rights conventions of the United Nations and the working norms of the ILO (International Labor Organization).

The certificate is valid for three years after which time a repeat audit shall be undertaken. The observance of specifications is examined at half-yearly intervals. Certification and monitoring are carried out by independent, SAI-accredited certification authorities, in this case the TÜV Rhineland. The new audit by TÜV Rhineland was completed on June 28, 2023, and the SA 8000:2014 certificate is valid for another three years.

The validity of the certificate can be checked under certificate registration no. 17 114 117234 at www.certipedia.com.

TÜV tested (German Association for Technical Inspection)

Since June 2011 Tatonka Production Plant Mountech Co. Ltd. is certified according to SA8000. This internationally recognised standard is the confirmation that our company observes the working and social standards required by ILO and UN conventions.

In December 2010 the Mountech company applied for certification to SA8000 standard of the TÜV Rhineland. After six months of intensive employee training and customization to detailed specification of the comprehensive rules and regulations, and also according to design, the production plant passed the test. The fact that this certificate was issued within such a short period of time is also good evidence of the high quality of work conditions in Mountech and for the dedication of all its employees.